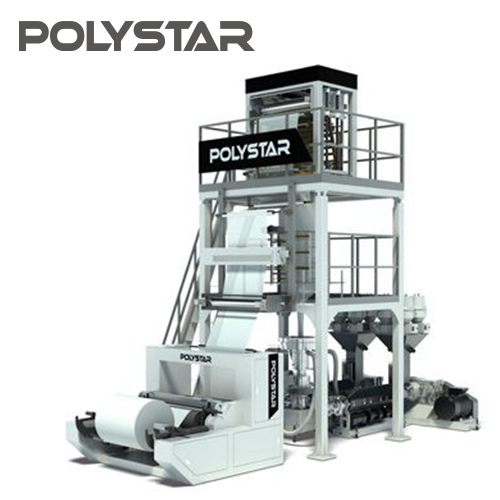

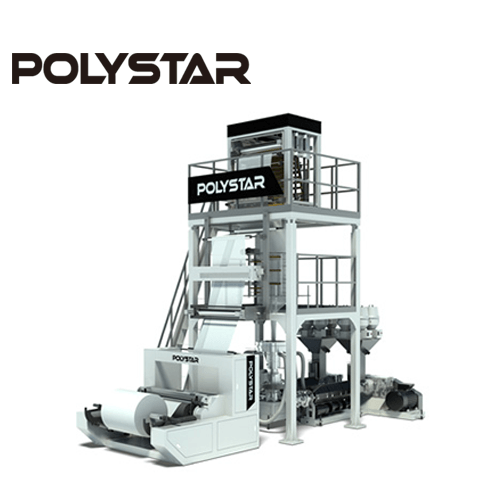

LD/LLDPE High Speed Blown Film Machine (AKB-LD/LLDPE)

Categories : Blown Film Extruders

LD/LLDPE HIGH SPEED BLOWN FILM MACHINE( AKB-LD/LLDPE)

PP High Speed Zipper Blown Film Machine (APZ-55/45)

Categories : Blown Film Extruders

PP HIGH SPEED ZIPPER BLOWN FILM MACHINE

ABA Double Die Blown Film Extruders

Categories : Extrusion Dies / Dies Heads

The main characteristics of these kind of Extruder is available to use two or more materials to manufacture film. HSIN LONG supply customized machine specifications for different output, material, film width, film thickness. Further, it reduces the waste of material cost since it allows to add CaCo3, recycled material and color masterbatch in the middle layer for different using.

ABA Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

● ABA 3 Layer Co-extrusion ● Film Width from 500~1500mm ● Extruder Dia: 40mm,45mm, 55mm, 65mm ● Material: HDPE,LDPE, LLDPE,CaCO3, Additives ● Output: 45~150 kgs/hr

3-Layer ABA Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

3-LAYER ABA CO-EXTRUSION BLOWN FILM MACHINE Extruder 3-Layer (ABC) PE Group/PP/Recycled

ABA Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Offering a wide range of Plastic Film Blowing Machines and its related components which are available to all the countries is what HSIN LONG keeps working on. For Three Layers ABA Co-Extrusion Blown Film Machine which characteristic is focus on its well performance and changing speed of the materials is extremely fast. It saves more time for customers to change the material and shorten the labor time. Further, It lowers the material change time and reduces the material wastage as well which is the biggest advantages of this type of plastic film blowing machine.

HDPE ABA Multi-Layer High Speed Blown Film Line

Categories : Blown Film Extruders

Kung Hsing HDPE ABA Multi-Layer High Speed Blown Film Line

3 Layer Co-extruded HDPE/LDPE/LLDPE

Categories : Co-Extrusion Blown Film Machines

Film width up 500 to 1500mm(or more) 40mm or 45mm or 55mm or 65mm screw Industrial Packaging

LE-ABA Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

3-LAYER (ABA) PE GROUP_PP_RECYCLED

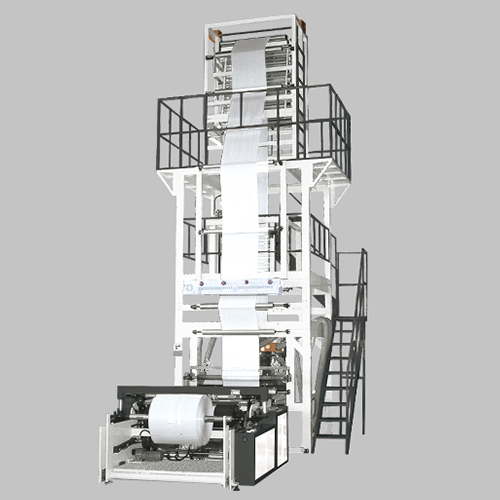

3-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Application for greenhouse sheet, agricultural films, construction sheets, food packaging, sacks, shrink films, shrink hood films, and more. Max. film width of up to 4.2 m (8.4 m for single-layer-opened films) It supports a wide range of raw materials such as HDPE, LDPE, LLDPE, EVA, MPE, PP, and others. The machine is equipped with three sets of gearboxes and motors for independent control. Optionally, a 360º Oscillating Nip roller device can be added to ensure uniform film thickness and improve the performance of the rotary die device. The machine can be equipped with a "Waste Film Recycling Machine" which enables direct feeding of waste film into the screw, eliminating any waste plastic film and reducing costs. Please note that the models shown here are not exhaustive. If you require larger extruders, please feel free to contact us.